LAMINATED GLASS

Offering a host of advantages Integral Seal’s Laminated Glass is the ideal option when designing for architectural applications large and small.

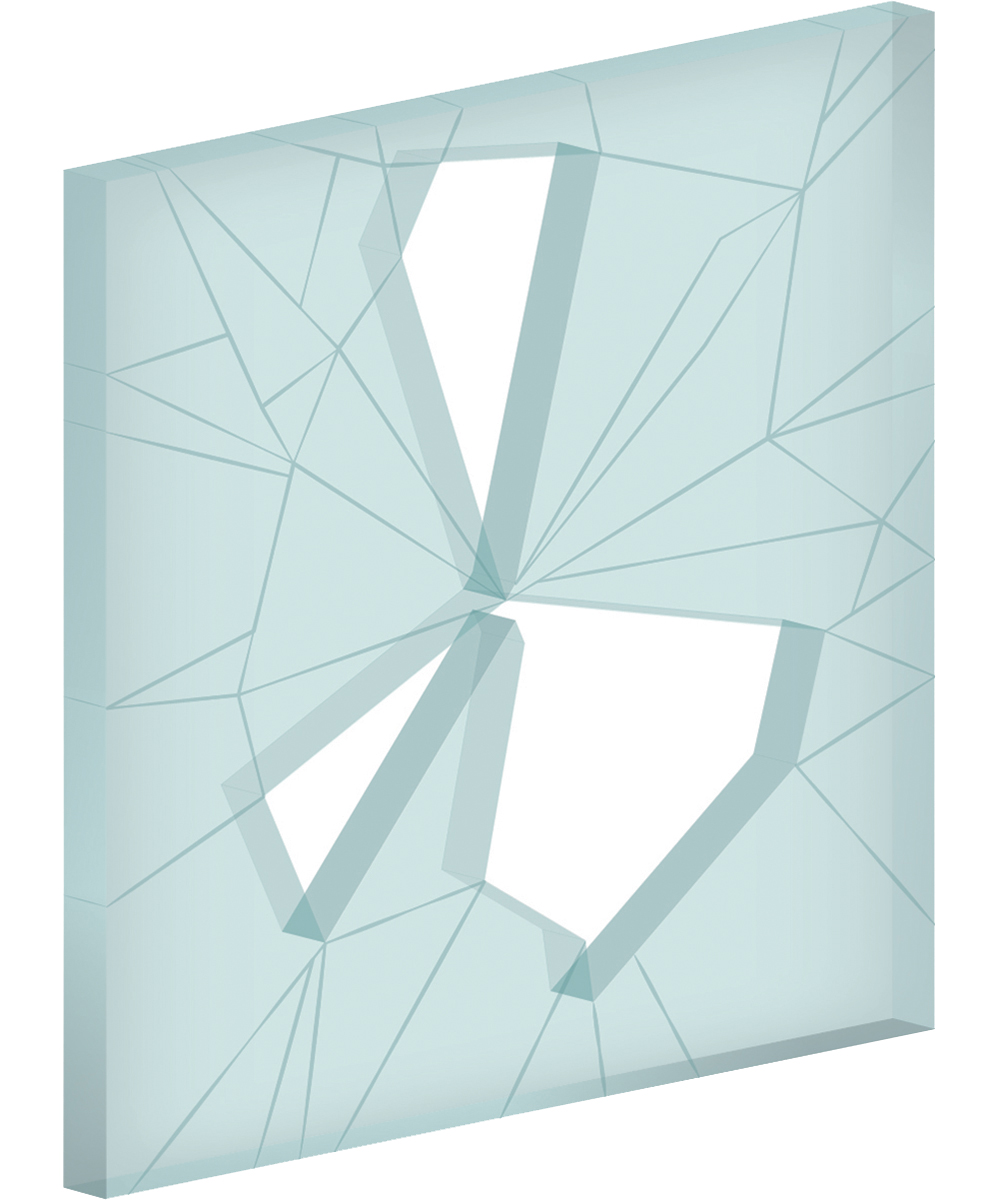

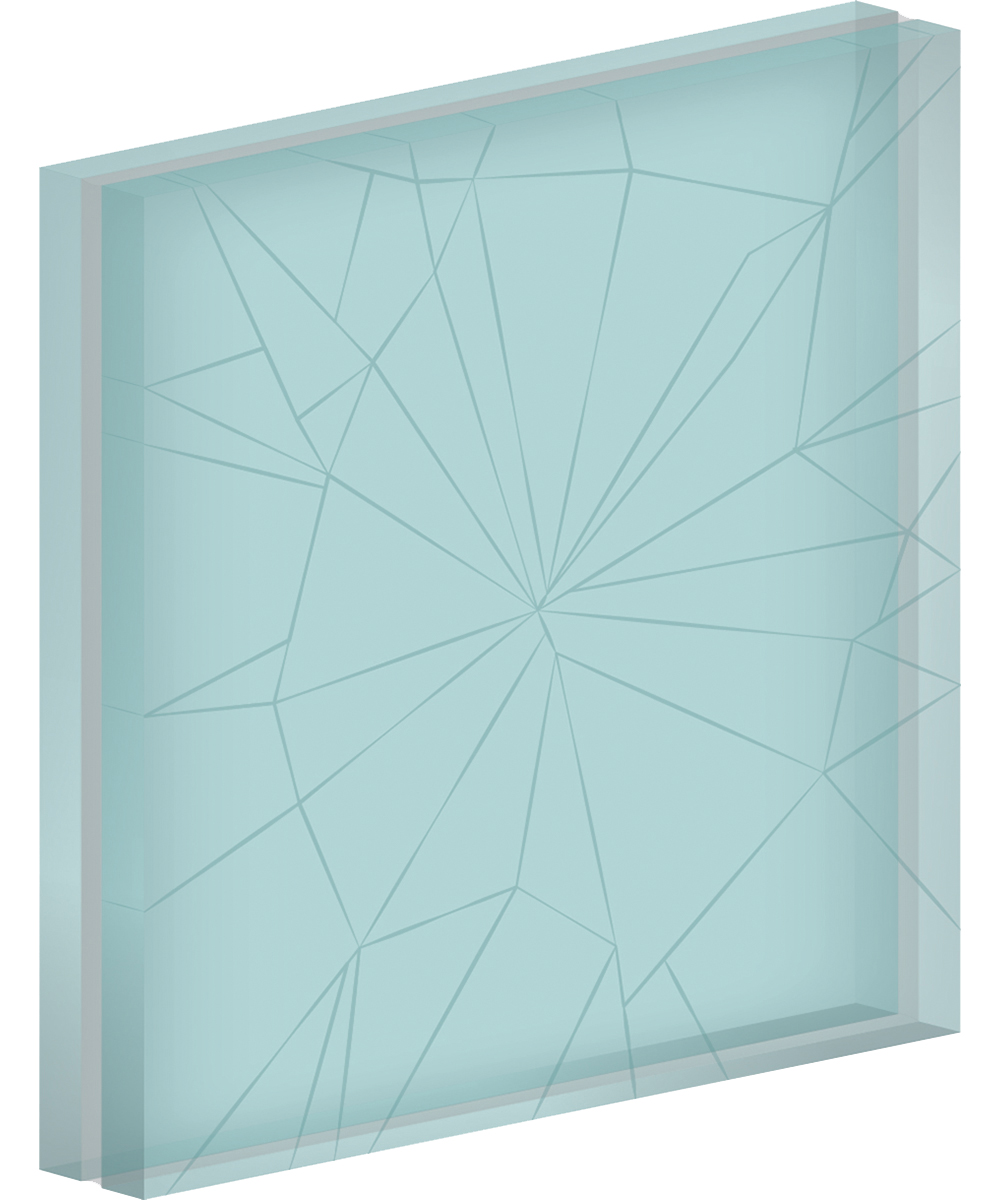

Laminated panels are a form of safety glass that are manufacture to hold together and remain secure when shattered. In the event of breakage, they are held in place by a specialized interlayer called EVA (ethylene-vinyl acetate). This interlayer holds firm upon impact remain bonded under high strength and preventing unsafe large sharp pieces from falling away. The result is a “spider web” cracking effect when impacted, which unlike single panels, is not enough to completely pierce the glass.

Its various architectural applications generally stem from the possibility of human impact where the glass could fall if shattered. Many building codes now require laminated glass to be used particularly for exterior balconies containing glass balustrading. Not only are laminated panels safe but they are also secure and can be used as theft protected, especially if panels have also be tempered. These custom tempered make-ups become exceptionally tough removing the need for wire mesh or steel bars.

Glass Comparison

Broken Single Panel

Broken Laminated Panel

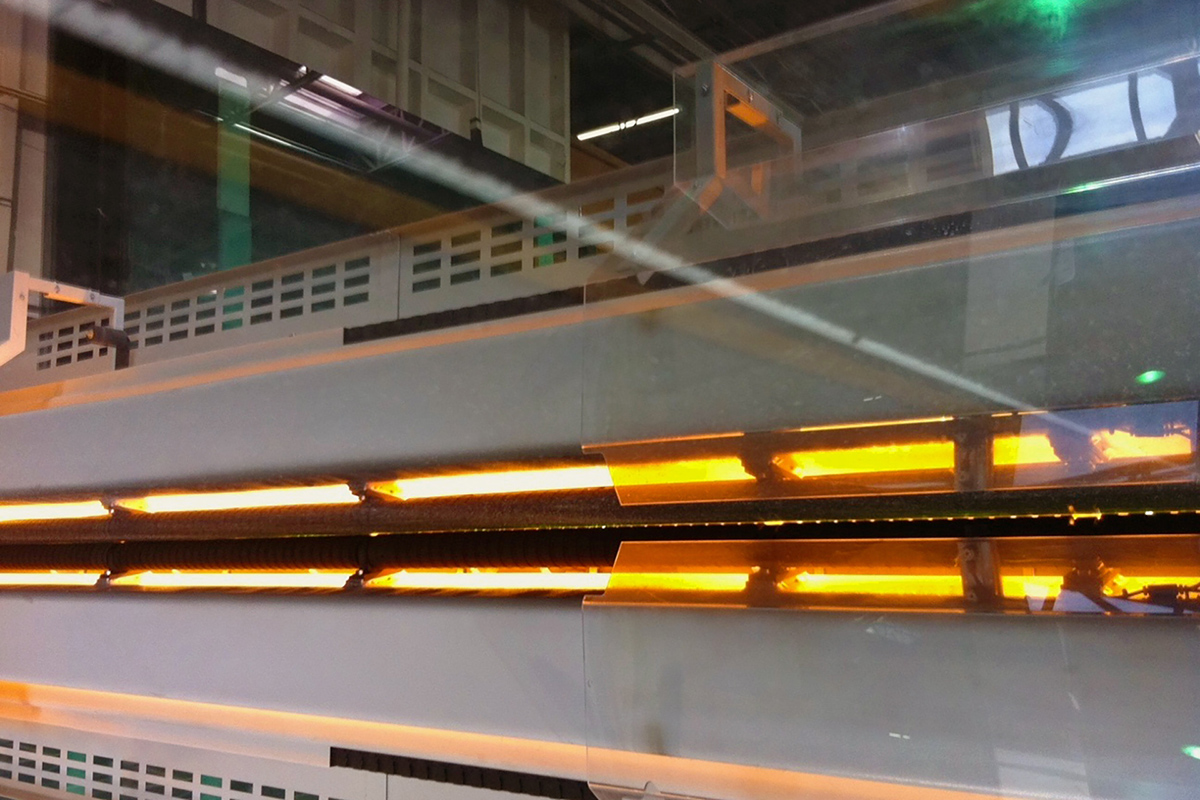

Another benefit to laminated panels is increasing the sound insulation rating of a glass window. Testing found significant improvements in sound attenuation compared to single monolithic glass panes of the same thickness. The benefits continue when laminating performance glass panels, creating a truly custom option for whatever the project may require. Integral Seal’s lamination line allows panels to be cut much faster and more efficient than by hand removing excess waste thanks to the computerized optimization software. The process is carried out by our specialised production equipment which scores, cuts, heats and trims the interlayer all at the push of a button, removing human error and giving a far more precise finished product.